MarketPulse Snapshots: 3-D Printing: the Next Smart Phone or the New Pet Rock?

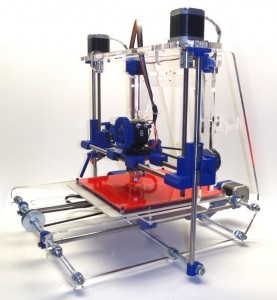

3-D printers, which use plastic resins and other materials to create three-dimensional objects, have been around since the early 1980s. The market for 3-D printing is currently estimated at $3.8 billion, and is expected to reach $16.2 billion by 2018. Small business applications are manifesting in fields like engineering, jewelry making, and architecture. These early adopters are using the technology mostly for prototyping, creating replacement and intricate parts, and for making customized gifts.

3-D printers, which use plastic resins and other materials to create three-dimensional objects, have been around since the early 1980s. The market for 3-D printing is currently estimated at $3.8 billion, and is expected to reach $16.2 billion by 2018. Small business applications are manifesting in fields like engineering, jewelry making, and architecture. These early adopters are using the technology mostly for prototyping, creating replacement and intricate parts, and for making customized gifts.

Small businesses who’ve embraced 3-D printing have found that it offers huge productivity and cost-saving advantages.

For example:

- An eyewear manufacturer cut 90 days from its production cycle when they started using a $3,000 3-D printer to create their design prototypes.

- Entrepreneur Magazine reported on a 130-person company called ClearCorrect that produces invisible braces. Before the move to 3-D printing technology, the expensive milling equipment used in the manufacturing process took up huge amounts of space, had to be reset often, and was subject to frequent breakdowns. Now, with 3-D printing, the company can run batches of 60 to 70 models at once, taking five minutes each, vs. 13 minutes with milling. The 3-D machines require 6,000 feet less floor space and 4-5 operators instead of 10-15.

Right now the possibilities and potential impacts of 3-D printing are only just emerging, and lots of questions about its impact on global labor, intellectual property, weapons control, distributed manufacturing, and many other things are still to be answered.

Comments

MarketPulse Snapshots: 3-D Printing: the Next Smart Phone or the New Pet Rock? — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>